Steel Vs. Aluminum for Construction: Cost and Major Uses

Steel Vs. Aluminum for Construction: Basic Comparison

December 18, 2020

Stainless Steel for Disaster Prevention: Strength and Elasticity

January 1, 2021In part one of this two-part blog series, we went over some basic differences between structural steel and aluminum when it comes to construction needs. These are two of the most common metal types used in the construction world, and choosing between them is often a role a general contractor or another within the process will be tasked with.

At Wasatch Steel, we’re proud to offer a wide range of steel sheet, steel bar, steel tube and numerous other high-quality steel materials for any construction need, large or small. We’re also happy to assist our clients with the selection of the ideal material for any construction application, whether public-facing or otherwise. Here’s a further breakdown of these two materials, including the cost differences and the common uses you’ll generally see for each in the construction world.

Cost Factors

Cost is obviously a major factor for any construction project and its materials, and this is one area where there isn’t necessarily a concrete “winner” between steel and aluminum. This is because the price of both will change and fluctuate over time based on supply and demand, both around the world and in your general area. Factors influencing supply include fuel costs, price and availability of alloys like iron and bauxite, and more.

That said, steel is generally the cheaper item on a per-pound basis. There are exceptions here, but in most cases, one steel spinning will cost less than one identical aluminum spinning due to the simple cost of raw materials involved.

Where are these two materials commonly used within the construction world? We’ll finish off our series by discussing this.

Common Steel Uses

Due to its high strength, steel is an ideal material for many baseline structural elements within construction. It’s both ductile and relatively flexible, as well, which also increase the number of applications it can be used for. You’ll find it commonly used in areas such as:

- Commercial and residential building frames, especially those built in recent years.

- Industrial and commercial garages or similar structures.

- Commercial skyscrapers and other tall buildings.

- Municipal infrastructure projects, including major ones like railways, public tunnels, bridges and more.

- Reinforcement bars for numerous previous buildings that may be lacking in support qualities.

Common Aluminum Uses

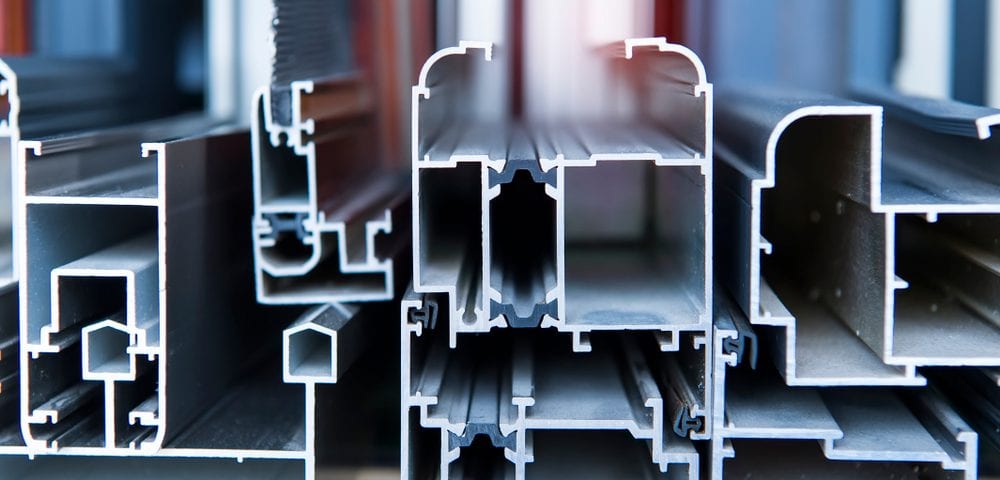

Aluminum, meanwhile, has a great strength-to-weight ratio and is also highly malleable, meaning it can fit into unique shapes and areas. However, it’s not as strong as steel and has some different applications as a result. It has two common alloys with different potential uses:

- 6061 aluminum alloy: A versatile alloy that’s ideal for roofing, siding, frames, bridge decks and more.

- 6063 aluminum alloy: Usually used for ornamental needs like window and door frames or architectural trim.

For more on steel versus aluminum for construction purposes, or to learn about any of our steel services, speak to the staff at Wasatch Steel today.